- All Products

- Hubei Tianxin Petrochemical - Quick opening blind plate clamp filter

Product Introduction

This product has been awarded a national patent and is widely used in the fields of petrochemicals and fluid technology. If no filter is installed in front of the fluid pipelines, impurities in the pipelines will not be removed, which will inevitably affect the accuracy of the medium and fail to protect the pump. This will pose safety hazards to the normal operation of the storage area. The current filter is a traditional one. Although it alleviates the above-mentioned industrial and mining conditions to some extent and provides certain protection, it is very inconvenient to install, dismantle, clean, and inspect. It wastes a lot of manpower, material resources and financial resources, increases labor intensity, and has a certain impact on the production progress.

Open the blind plate clamp type filter quickly. It has a compact structure, is convenient for operation and management, and features the ability to filter impurities in the pipeline and protect the starting pump. It also has the advantages of quick and convenient installation, disassembly, cleaning and inspection. It has a wide range of applications and is suitable for pumps in various fluids.

Product Features

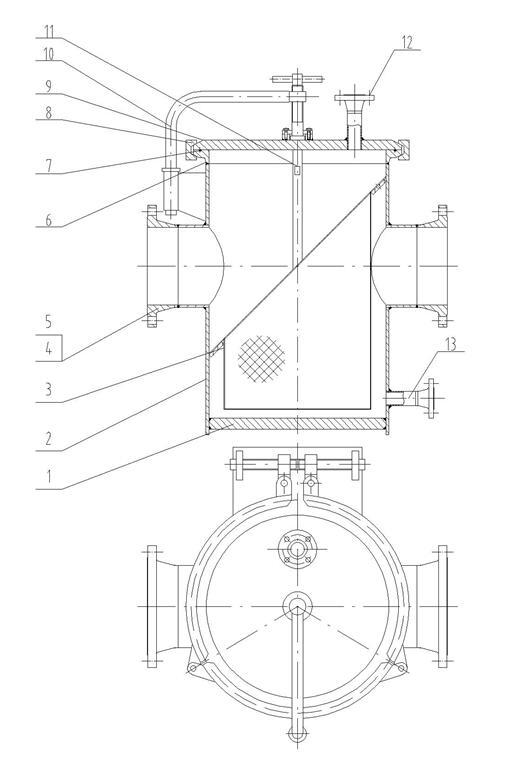

The blind plate is equipped with a rotating arm assembly. The screw rod of the assembly serves as the lifting mechanism for up and down movement. The clamp assembly and the positive and reverse screws of the assembly tighten the screw rod mechanism to secure the blind plate and the lower flange together. The structure is compact, facilitating operation and management. It is quick and convenient for installation, disassembly, cleaning, and inspection.

Working Principle

When the liquid enters the inner cavity of the filter, it is filtered by the filter screen, and solid impurities and foreign substances are blocked at the bottom of the housing. The clean liquid after filtration flows out from the outlet, thus achieving the filtering purpose. During cleaning, loosen the bidirectional screw to separate the clamps from each other. Use the lifting screw to lift the upper cover, then move the upper cover to one side to remove the filter screen for cleaning.

Product Structure Diagram

Product Specification Model

Model | Specification | D | L | H1 | H |

TXKGQ-1 | DN80 | 168 | 340 | 260 | 400 |

TXKGQ-2 | DN100 | 219 | 420 | 310 | 470 |

TXKGQ-3 | DN150 | 273 | 500 | 430 | 620 |

TXKGQ-4 | DN200 | 325 | 560 | 530 | 780 |

TXKGQ-5 | DN250 | 426 | 660 | 640 | 930 |

TXKGQ-6 | DN300 | 478 | 750 | 840 | 1430 |

TXKGQ-7 | DN350 | 500 | 800 | 600 | 1890 |

TXKGQ-8 | DN400 | 550 | 840 | 700 | 2280 |

TXKGQ-9 | DN450 | 600 | 960 | 700 | 2350 |

TXKGQ-10 | DN500 | 700 | 1060 | 900 | 2650 |

TXKGQ-11 | DN600 | 813 | 1215 | 1100 | 2950 |

TXKGQ-12 | DN700 | 1016 | 1420 | 1250 | 3350 |

Specifications

| Companies | Hubei Tianxin Petrochemical Equipment Co., Ltd. |